Manufacturer Of Injection Skid Packages

Chemical Injection Skid Manufacturer

DENCIL is one of the top leading Chemical Injection Skid Manufacturer in India. Our offered Injection Systems is advanced and is used in many sectors. Thus, we ensure timely maintenance and quality assurance of the Injection Skid we manufacture.

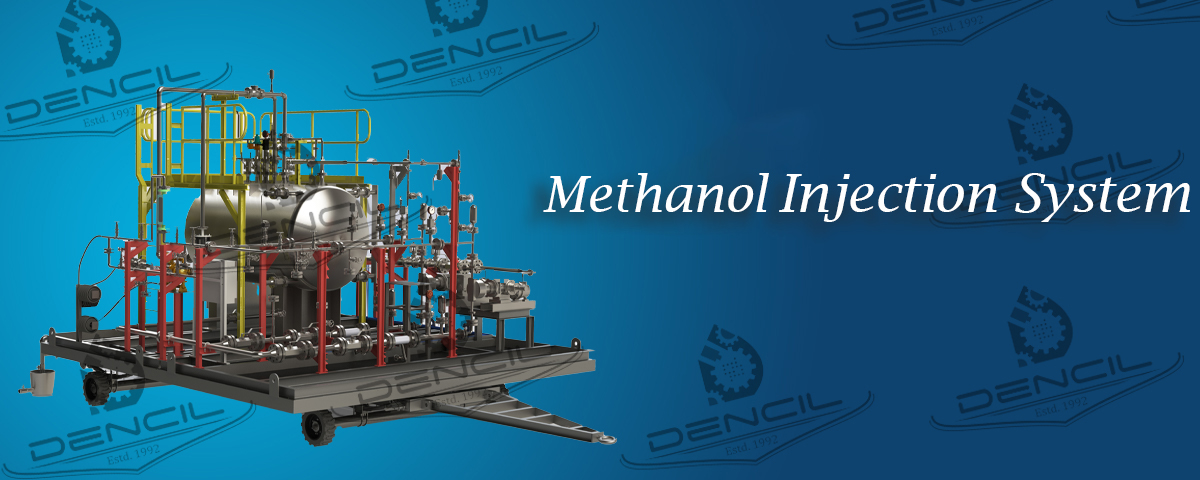

We specialize in manufacturing and supplying a wide range of Containerized Injection Skid, Mercaptan Injection Skid, Poratable Methanol Injection Skid & Many More !..

CHEMICAL INJECTION SKIDS is a part of our Skid Packages, we guarantee maximized operational performance and precise dosage and control of chemicals through our industry leading pneumatic, electric, or solar chemical injection pumps, coupled with our own manufactured DENCIL brand API 675 Diaphragm & Plunger Pumps. Customers requiring an integrated chemical injection solution that solves their operational challenges with real-time control and diagnostics, through existing SCADA networks, can now do so with DENCIL’s skid package products. We believe in simplifying and standardizing our chemical delivery solutions.

Chemical injection may function continuously or intermittently, and it can be used in a wide range of settings for many different purposes in marine and offshore industry. Our one stop shop approach provides the benefit of not having to source components from different vendors eliminating the issues that arise from mixing and matching equipment.

Dencil’s medium and high pressure chemical injection system / package and other wash water injection package are known in upstream or downstream oil or gas industry for its EOR, well cleaning, improving pipeline flow or oil recovery, and corrosion prevention advantages.

Through this kind of oil industry system, water is injected into the reservoir to increase pressure and stimulate the production. It is also used to displace or sweep the oil from the reservoir, pushing it towards water injection wells which are usually found in both onshore and offshore. Only 30% of the oil in a reservoir is extracted so the system is needed to increase that percentage and maintain the reservoir’s rate of production for a long period of time.

A team of experienced and qualified engineers having complete knowledge of design standard & operation of the skid are dedicated & deployed for manufacturing of the same.

DESIGN STANDARDSAmerican (API, ASME, ANSI, AISC, AVI, ASCE, IBC, UBC, NEMA)

European (Euro, PED, TEMA)

Indian (BIS, ISI)

FOLLOWING ARE SOME OF OUR STANDARD CHEMICAL DOSING & INJECTION SYSTEMS.,

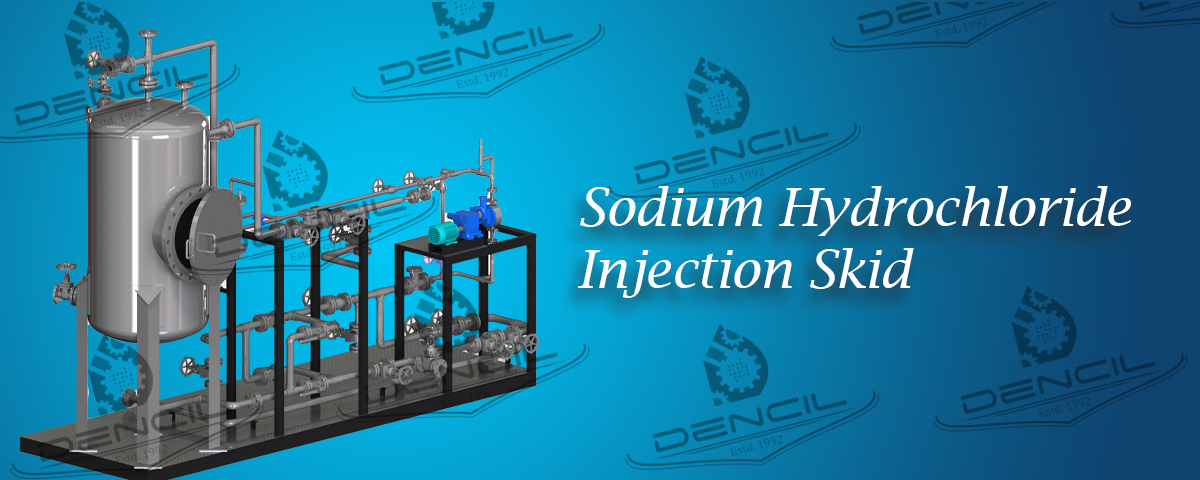

- Sodium Hypochloride Injection Skid

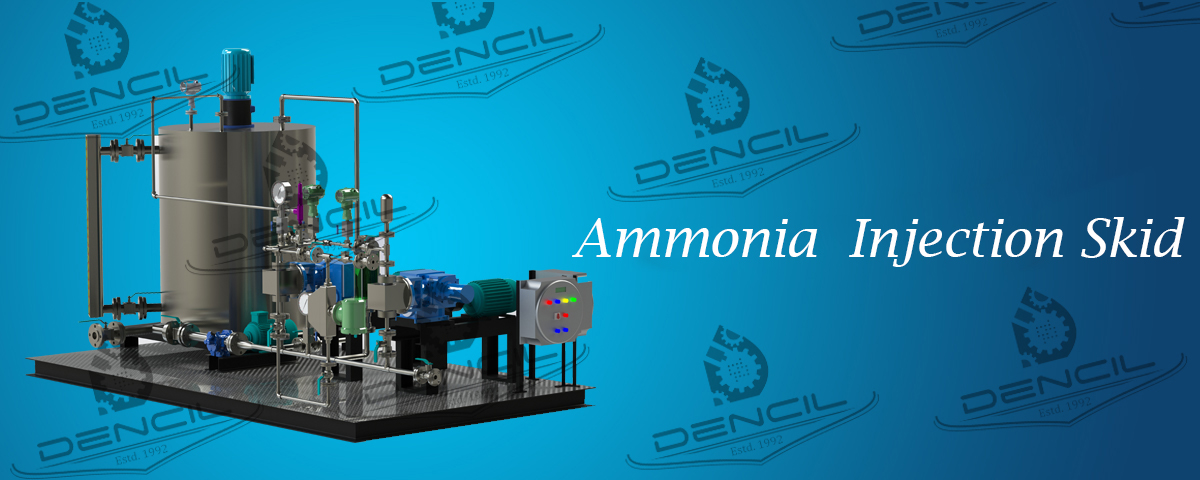

- Ammonia Injection Skid

- Biocide Injection Skid

- PPD Injection Skid

- Water Injection Skid

- Reverse Demulsifier Injection Skid

- Demulsifier Injection Skid

- Carbonate Corrosion Inhibitor Injection Skid

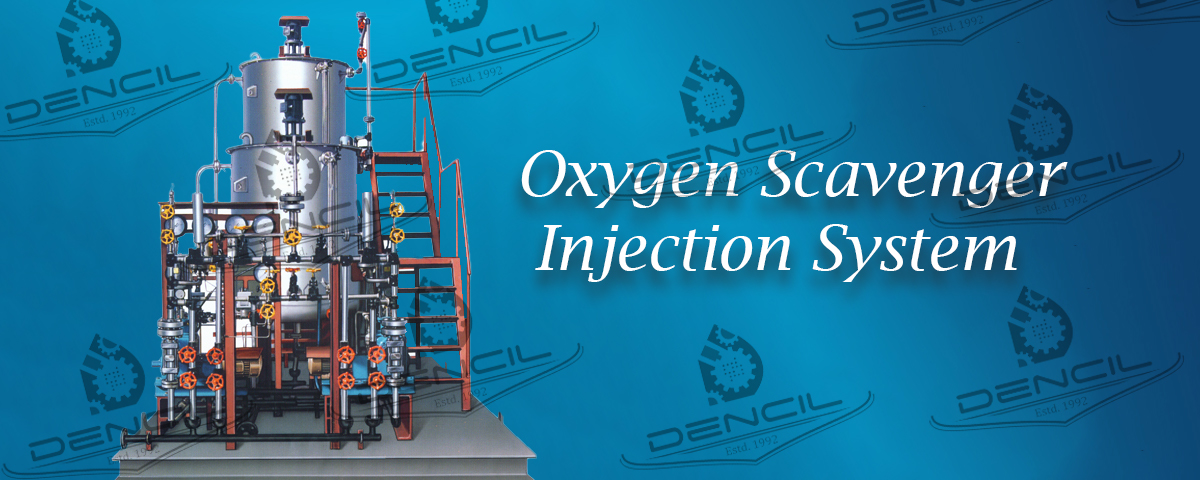

- Oxygen Scavenger Injection Skid

- Methanol Injection Skid

- Mercaptan Injection Skid

- Amine Injection Skid

- Corrosion Inhibitor Injection Skid

- Mercaptan Injection Skid

- Dye Injection Skid

- Anti Oxidant Injection Skid

- Static Dissipater Injection Skid

- Drag Reducing Additive Injection Skid also known as DRA Skid or DRA Injection Skid., & Many More ...